Make The Most Of Lots Security With an Advanced Stretch Covering Machine for Safe Transportation

Advanced stretch covering devices supply an ingenious service, covering lots with identify accuracy to protect against moving during transportation. With a collection of features such as flexible film tension and automated performance, these makers deliver consistent upright and horizontal stability while decreasing damages danger. Just how do these devices specifically enhance load stability and efficiency?

Comprehending the Function of Stretch Covering in Safe Transport

While lots of might ignore its significance, stretch covering plays a vital role in ensuring the safe transportation of items. This process includes making use of a very elastic plastic film that is covered around items, typically on a pallet. The elastic recovery of the cover firmly secures the items together, protecting against motion during transport.

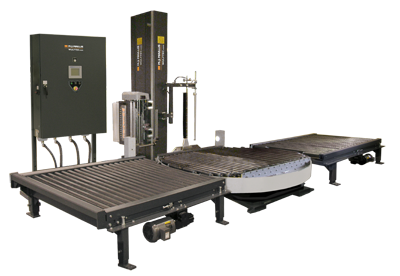

Trick Attributes of Advanced Stretch Wrapping Machines

In the realm of logistics and supply chain management, advanced stretch wrapping equipments have actually arised as a game-changer. These devices are identified by a number of crucial features that distinguish them from their predecessors.

Advanced stretch wrapping equipments also include pre-stretch capabilities. This function allows the film to be extended before being put on the load, optimizing movie usage and minimizing costs. In addition, these machines have adjustable controls for movie stress, enabling modification based on tons size and shape.

Finally, these makers are furnished with incorporated lots cells, which accurately measure the weight of the lots during the covering procedure. This attribute makes certain the device changes its procedure based upon the weight, thus protecting against damages and ensuring the lots's secure transport. Therefore, progressed stretch covering makers use a mix of automation, effectiveness, cost-effectiveness, and safety.

Just How Stretch Covering Machines Enhance Tons Security

Ensuring that lots continue to be steady during transport is an important element of logistics, and one that advanced stretch wrapping equipments stand out in addressing. These machines function by covering the load in a safety film that holds all products safely together. This lowers the danger of items dropping or changing during transportation, thus improving load stability.

The devices employ a Discover More Here sophisticated wrapping method that offers not just upright however additionally straight security. This dual-axis security additionally strengthens the tons and decreases the chance of damages or loss. The uniform stress used by the device throughout the covering process guarantees that the lots is protected and portable.

Potential Price Financial Savings With Efficient Stretch Wrapping

Beyond improving tons stability, progressed stretch wrapping machines additionally supply significant possibility for expense savings. These equipments minimize the requirement for manual work, therefore lowering pay-roll costs. They also function faster and extra efficiently than human beings, leading Full Article to increased productivity.

Using advanced machines makes certain ideal use of stretch movie, which can lead to substantial cost savings in material expenses. Manual wrapping frequently brings about wastage because of irregular use film. A maker uses the best quantity of film, getting rid of wastage.

Additionally, the enhanced load security reduces the threat of damages during transport. This can possibly save organizations from costly product losses and linked replacement expenses.

Last but not least, the machines need marginal upkeep, which equates right into reduced repair and upkeep expenses.

Selecting the Right Stretch Covering Device for Your Company Requirements

While the advantages of innovative stretch wrapping devices are obvious, choosing the ideal one for your particular organization demands can be a complicated job. High-volume procedures would certainly profit from automated equipments with greater rates, while semi-automatic machines might be sufficient for smaller sized organizations. A comprehensive assessment of these aspects can assist services towards the ideal stretch wrapping device, thus guaranteeing safe transportation of their items.

Conclusion

In conclusion, progressed stretch wrapping makers are important in guaranteeing tons security throughout transport. They supply key functions like adjustable movie stress and automation, offering both straight and upright safety and security. By minimizing the threat of damages, they can add to substantial expense savings. Businesses need to think about investing in an ideal stretch wrapping device, even more boosting security and efficiency within their supply chain.

Advanced stretch wrapping makers offer a cutting-edge solution, covering loads with determine accuracy to stop changing during transportation.Making certain that loads continue to be secure during transport is a crucial element of logistics, and one that progressed stretch covering makers stand out in addressing.Beyond improving lots stability, advanced stretch covering devices additionally offer address significant capacity for cost financial savings. High-volume operations would profit from automated machines with greater speeds, while semi-automatic equipments might be enough for smaller sized companies.In verdict, progressed stretch wrapping makers are vital in making certain load security throughout transportation.